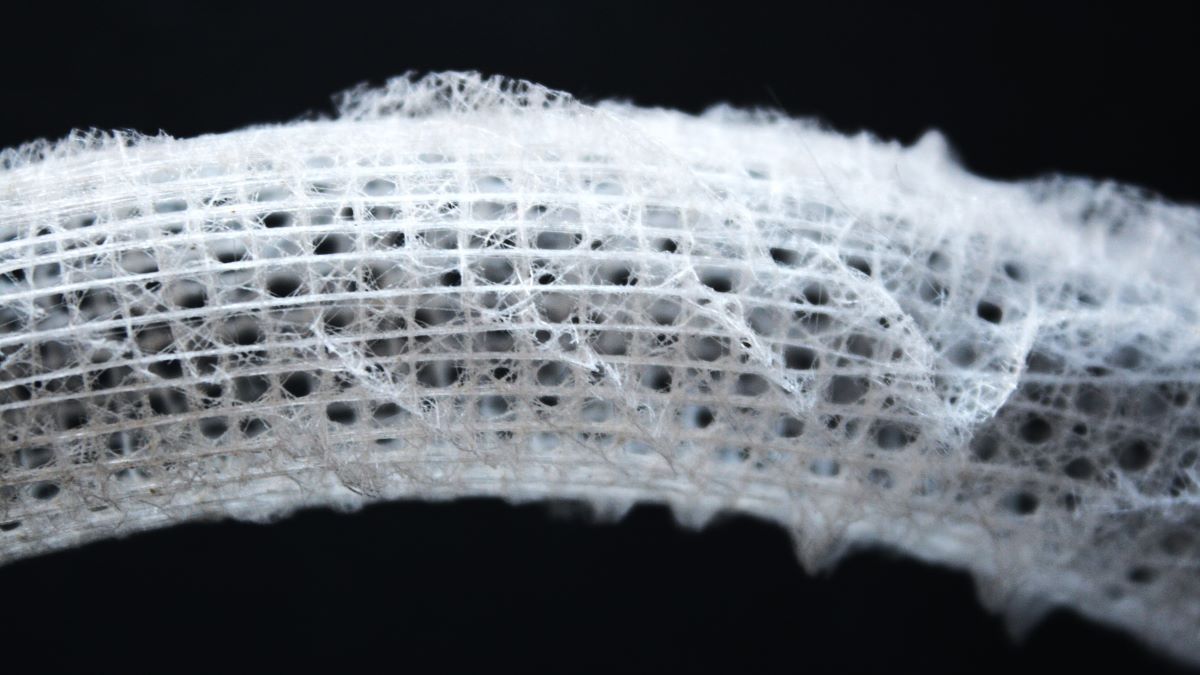

A sea sponge skeleton made of glass makes engineers wonder how construction materials could improve.

The sponge in question lives at the bottom of the Pacific Ocean, and is known as the Venus flower basket (Euplectella aspergillum). Build its intricate skeleton shaped like a silica basket: the main material in sand and glass.

The skeleton network pattern has inspired Australian engineers to develop a new material with incredible compression and rigidity resistance.

It is known as a “auxiliary” material, which means that it contracts when compressed.

“While most materials are delighted when they stretch or fatter when they crush, such as rubber, aid does the opposite,” says Dr. Jiaming ma from the Rmit University, the lead author of a study describing the new material in the newspaper Composite structures.

“Auxotics can absorb and distribute impact energy effectively, making it extremely useful.”

MA and the team of the CMR Structures and Materials Center modeled its double network design in the Marina sponge. It forms a uniform square grid reinforced by 2 sets of diagonal strut.

They tested the design using computer simulations and a 3D printed sample made of thermoplastic polyurethane and discovered that the network is 13 times more rigid than existing helper materials.

It can also absorb 10% more energy while maintaining its help behavior, compared to existing designs.

Notable material properties could be used to improve architecture and manufacture of certain products.

“Our auxiliary metamaterial with high stiffness and energy absorption could offer significant benefits in multiple sectors, from construction materials to protection and sports equipment or medical applications,” says Dr. Ngoc San Ha Ha, corresponding author of the study.

Now they plan to produce design steel versions to test with concrete and onslaught earth structures, a construction technique that uses compacted natural raw materials.

“We are developing a more sustainable construction material using the unique combination of auxiliary, rigidity and energy absorption of our design to reduce the use of steel and cement in construction,” says Ma.

“Its auxhetic and absorbent features of energy could also help cushion vibrations during earthquakes.”

Do you care about the oceans? Are you interested in the scientific developments that affect them? So our email bulletin Ultramarine It is for you.

Read more

#material #inspired #glass #skeleton #marine #sponge