Preventive maintenance is critical when it comes to industrial machinery. Good practices are even more essential for machinery, such as alternative compressors, which play a vital role in many companies. This article offers a guide on the maintenance of its alternative compressors to guarantee optimal performance.

Understanding the maintenance of the alternative compressor

Quality maintenance of a Alternative compressor It begins to understand how the function of each part works. Depending on the use and model, a compressor can have different needs and require different services.

The reciprocal maintenance of the compressor generally implies inspection, lubrication, cleaning and replacement of components. By keeping up with regular maintenance, you can reduce the risk of compressor failure and increase the general efficiency of the machine.

Proper maintenance also means taking the necessary precautions to avoid common problems. From seal failures to overload trips, these problems can be easily prevented with the appropriate maintenance regime.

An adequate maintenance program is also crucial. Depending on the type of compressor, the maintenance frequency may vary. Some companies may depend largely on their compressors and need monthly service, while others may only require a service several times a year.

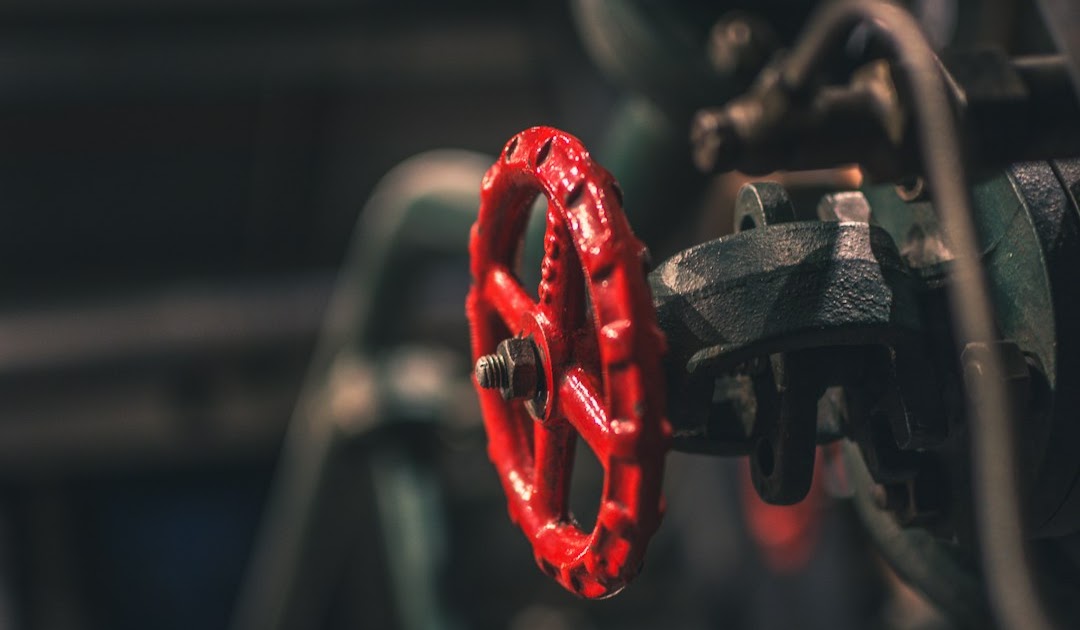

Parts of an alternative compressor to maintain

The key parts of a compressor that require maintenance include valves, pistons, rings and cooling system. Regular cleaning can avoid the accumulation of dirt and debris, which can make the machine work inefficiently.

Valves and pistons often suffer wear due to intense compressor pressure. Regular inspections can help identify old pieces before they lead to substantial problems. Replacing worn parts as necessary can help maintain compressor performance.

The rings and stamps of the compressor piston play a crucial role in the maintenance of the pressure. Therefore, they require regular inspection to ensure that they are in good condition and replace them as necessary.

The cooling system, particularly air -refrigerated compressors, also requires regular maintenance. Ensure that the system is efficient can help maintain the correct operating temperature and avoid overheating.

Tips for maintaining the alternative routine compressor

An essential advice for routine maintenance is to maintain a detailed record of each service performed. This can help monitor compressor health, predict potential problems and plan the necessary maintenance.

Using the correct lubricant type And verifying it is often another aspect of critical maintenance. Always verify the manufacturer’s recommendations in search of appropriate lubricants, since using the incorrect can cause serious damage.

Listening to your compressor while it works can also be useful. Unusual noises could indicate a problem, and fast action can prevent a small problem from becoming a significant problem.

Finally, it is essential to develop a regular maintenance schedule and follow it consistently. Planned regular maintenance can avoid unexpected and expensive repairs.

Impact of regular maintenance on compressor efficiency

Regular maintenance can greatly improve the efficiency of a compressor to reciprocal. The proper service guarantees that all components work optimally, reducing energy consumption and, therefore, increase efficiency.

On the contrary, lack of maintenance can cause wear, lower performance and, ultimately, the decomposition of the machine. A well maintained compressor uses less energy, which finally saves costs.

Maintenance verifications also help avoid inactivity time due to damaged parts or system failures. When preventive measures are taken, work processes are less likely to be interrupted, which contributes to having a more productive tool.

Finally, the regular service provides peace of mind that its compressor is safe and suitable for use. Over time, the poorly maintained equipment can become dangerous, so regular controls promote safer operations.

In general, the understanding and implementation of adequate maintenance practices for alternative compressors is vital to improve the useful life and safety of the equipment. Use this basic maintenance guide to ensure that your compressors continue to function efficiently and safely. Do not allow the lack of maintenance to impact your business.

#Understanding #basic #concepts #alternative #compressor #maintenance #Business #Tech #World