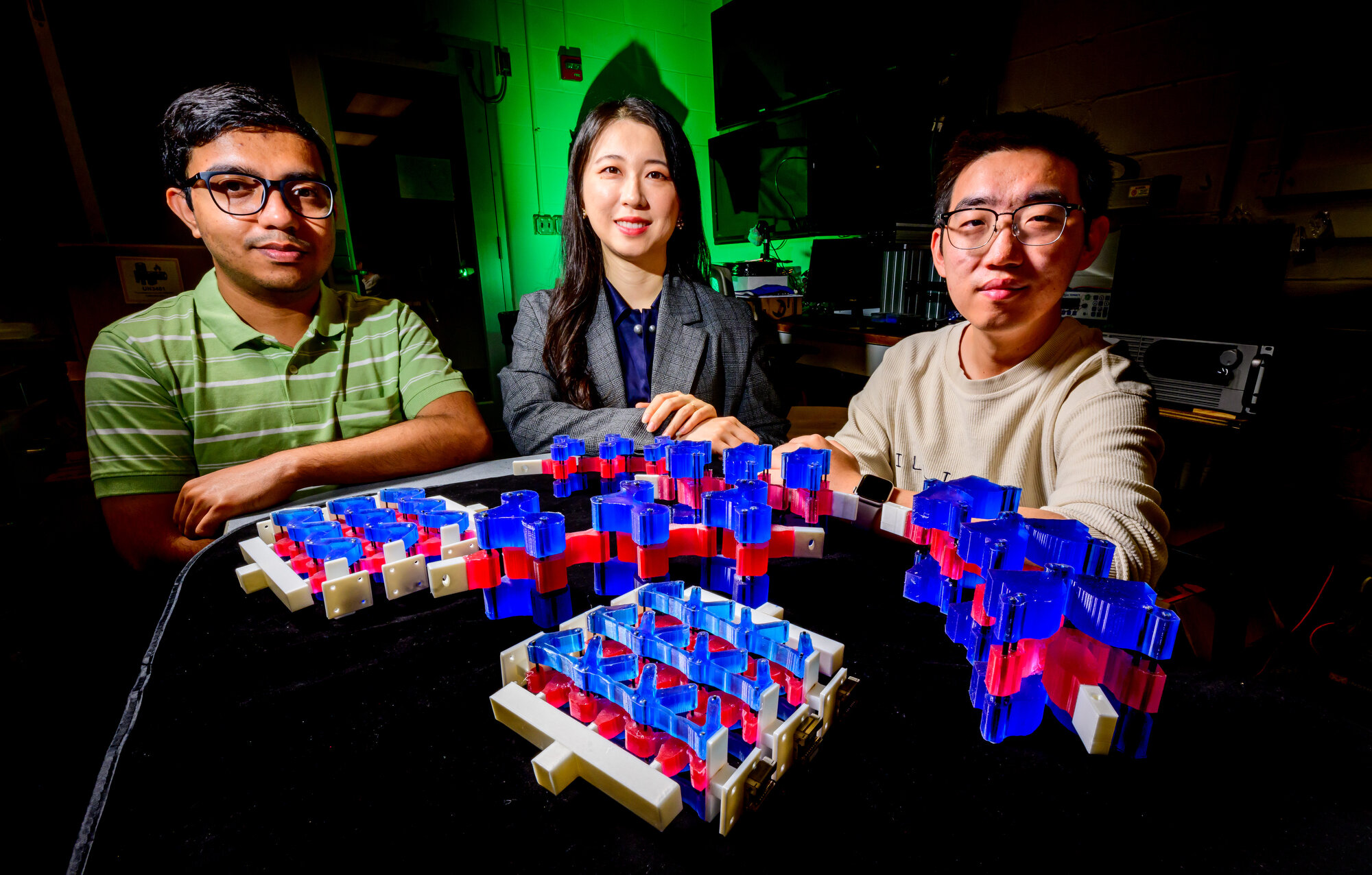

Illinois teacher, Shelly Zhang, center, with other researchers Rahul Dev Kundu, on the left, and Shi Zhao, on the right, have developed a multicapa synthetic material, similar to marine shells, where each layer responds to stress differently. Researchers imagine this technology that is used in things such as cars of car and portable bandages. Credit: Fred Zwicky

Millions of years of evolution have allowed some marine animals to cultivate complex protective shells composed of multiple layers that work together to dissipate physical stress. In a new study, engineers have found a way to imitate the behavior of this type of material in layers, such as Seashell Nacre, programming individual layers of synthetic material to work in collaboration under stress. The new material design is ready to improve energy absorption systems, such as portable bandages and cars with multiple stages responses that adapt to the severity of the collision.

Many previous studies have focused on reverse engineering to replicate the behavior of natural materials such as bone, feathers and wood to reproduce their non -linear responses to mechanical stress. A new study, led by the University of Illinois Urbano-Champaign, the professor of Civil and Environmental Engineering, Shelly Zhang, and Professor Ole Sigmund of the Technical University of Denmark, looked beyond reverse engineering to develop a framework for programmable multilayer materials capable of responding to local disturbances through interconnections to Micrescala.

The study findings are published In the newspaper Scientific advances.

“This work was born from a discussion with my collaborator, Professor Sigmund, about how we can already achieve some very extreme behaviors, but there is always a physical limit or an upper limit that individual materials can achieve, even with programming,” said Zhang. “That led us to consider what type of engineering some of the necessary crazy material behaviors could allow in real life. For example, extreme buckling behaviors could help dissipate energy for things such as car bumpers.”

It was then that the team directed their attention to biological materials with multiple layers that serve a different purpose, and how they could manufacture a synthetic material and use internal microsyle programming and optimization to control their response to stress and mechanical tension.

“We landed in the idea of designing multicapa materials with each layer capable of exhibiting different properties and behaviors,” said Zhang.

But not stop there, the team struggled to include the ability of individual layers to essentially collaborate collectively as one.

“Our new frame has several advantages over existing methodologies for non -linear voltage responses,” Zhang said. “Optimizes multiple nacre -shaped layers along with its interconnections in a continuous configuration, which significantly expands the design space compared to a similar work that involves a single layer configuration or network structures.”

During the manufacture, the team learned some lessons. The theoretical idea behind this work is to have an infinitely periodic material. Even so, the team must manufacture finite units, and it was expected that the theoretical material and real manufactured material exhibit different behaviors.

“The discrepancy we find is something that will always happen in real life,” said Zhang. “But we can take advantage of this information to intentionally program the sequence of the buckling of each of the individual cells in the assembly, store certain information inside and then we can decode the information. It was fascinating to capture this discrepancy and end up providing information necessary to improve the work.”

There is still a lot of work to do to expand manufacturing for this type of material, but Zhang said that a valuable thing learned from this study is that when people collaborate, they achieve much greater things.

“I think it works the same for materials,” Zhang said. “When different materials work collectively together, they can do things that are much more shocking than if they do things individually.”

More information:

ZHI ZHAO et al, not extreme linearity due to layers in layers through reverse design, Scientific advances (2025). DOI: 10.1126/SCIADV.ADR6925

Citation: Synthetic materials mimic sea shells to improve energy absorption (2025, May 16) recovered on May 24, 2025 from https://phys.org/news/2025-05-sintetic-materials-mimic-seeshells-nergy.html

This document is subject to copyright. In addition to any fair treatment with the purpose of study or private research, you cannot reproduce any part without written permission. The content is provided only for information purposes.

#Synthetic #materials #mimic #sea #shells #improve #energy #absorption